FG-Catalog Fiberglass Muaj zog thiab lub teeb yuag Fiberglass Khoom

Daim ntawv thov khoom: iav fiber ntau daim kab xev yog siv rau hauv kev lag luam: rwb thaiv tsev kub, fireproof, inflaming retarding, foob, thiab lwm yam, tshwj xeeb tshaj yog, nws yog siv rau lub sealing thiab kev tiv thaiv ntawm tag nrho cov hom ntawm lub tsev fireplaces.

Technical Overview:

Ua haujlwm kub:

550 ℃

Qhov Loj Loj:

Dav: 15-300 mm

Thickness: 1.5-5 hli

Standard ntev: 30M

Paub ntau ntxiv txog fiberglass

FIBERGLASS YARN

Cov txheej txheem ntawm kev hloov cov iav melted rau hauv fibers los ntawm cua sov thiab kos iav rau hauv cov fibers zoo tau paub ntau txhiab xyoo; Txawm li cas los xij, tsuas yog afer kev tsim kho kev lag luam thaum xyoo 1930s tau ua kom muaj kev tsim khoom loj ntawm cov khoom tsim nyog rau cov ntawv thov textile.

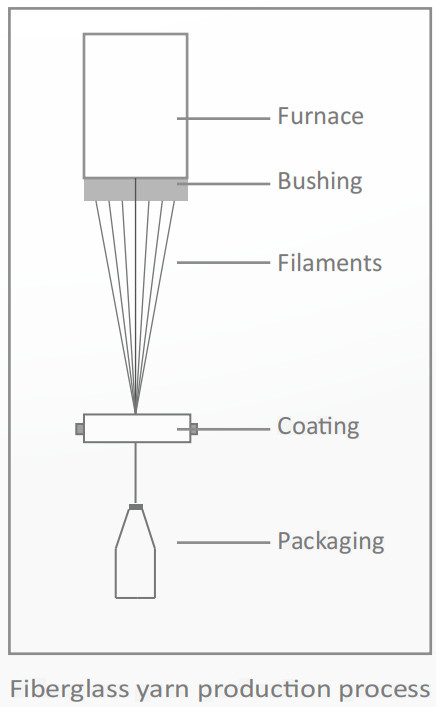

Cov fibers tau txais los ntawm tsib kauj ruam txheej txheem hu ua batching, melting, fiberizaton, txheej thiab ziab / ntim.

•Batching

Thaum lub sij hawm cov kauj ruam no, cov ntaub ntawv raw yog ua tib zoo ntsuas nyob rau hauv kom meej kom muaj nuj nqis thiab meej tov los yog batched. Piv txwv li, E-iav, yog tsim los ntawm SiO2 (Silica), Al2O3 (aluminium oxide), CaO (Calcium oxide los yog txiv qaub), MgO (magnesium oxide), B2O3 (boron oxide), thiab lwm yam ...

• Melting

Thaum cov khoom yog batched ces xa mus rau tshwj xeeb furnaces nrog ib tug kub ntawm txog 1400 ° C. Feem ntau cov cub tawg tau muab faib ua peb ntu nrog qhov sib txawv ntawm qhov kub thiab txias.

• Fiberizaton

Lub iav molten dhau los ntawm bushing ua los ntawm kev yaig-resistant platnum alloy nrog ib tug txiav txim tus naj npawb ntawm zoo heev orifices. Cov dav hlau dej txias cov filaments thaum lawv tawm los ntawm lub bushing thiab tau sib sau ua ke los ntawm kev kub ceev winders. Txij li thaum nro nyob ntawm no thov cov kwj ntawm molten iav yog kos rau hauv nyias nyias.

• Txheej

Cov txheej txheem tshuaj yog siv rau ntawm cov filaments los ua cov roj nplua nyeem. Cov kauj ruam no yog tsim nyog los tiv thaiv cov filaments los ntawm abrading thiab tawg thaum lawv tau sau thiab raug mob rau hauv cov pob khoom.

• ziab / ntim

Cov hlua khi tau muab sib sau ua ke rau hauv ib pob, tsim ib lub iav strand uas muaj ntau yam ntawm cov filaments. Cov strand yog raug mob rau ntawm ib lub nruas rau hauv ib lub pob tsim uas zoo li ib tug spool ntawm xov.

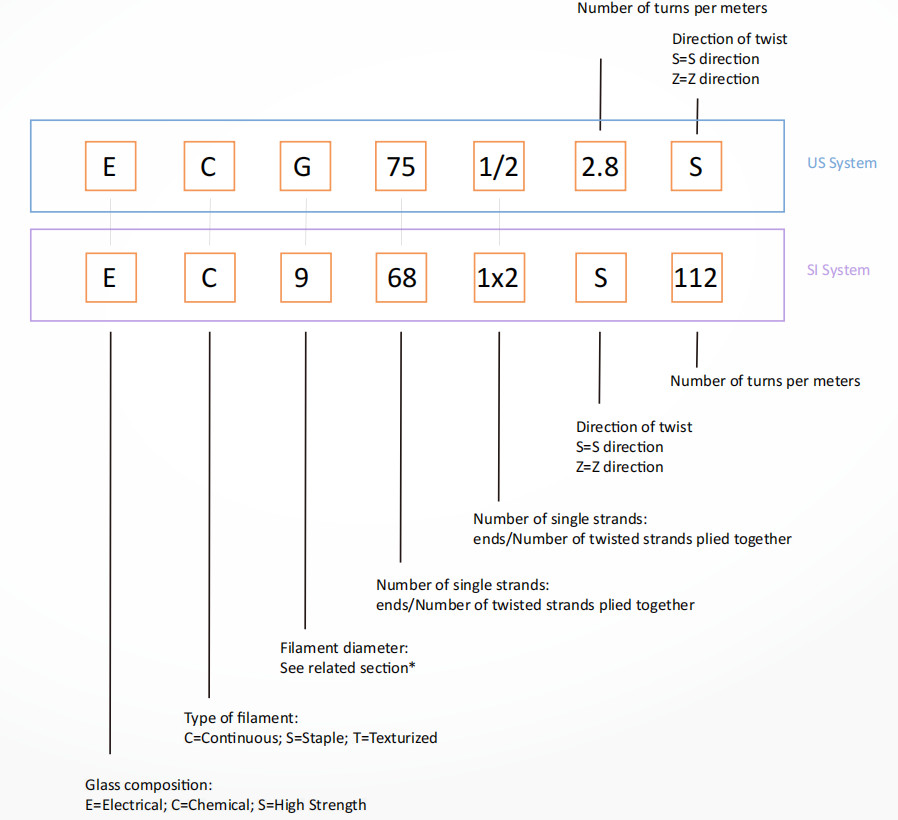

YARN NOMENCLATURE

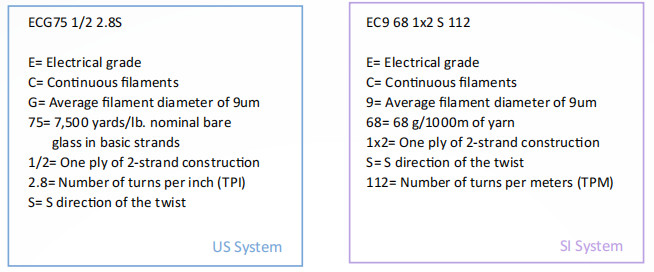

Cov iav fibers feem ntau tau txheeb xyuas los ntawm Teb Chaws Asmeskas kev cai system (inch-pound system) lossis los ntawm SI / metric system (TEX / metric system). Ob leeg yog internatonally lees paub ntsuas cov qauv uas txheeb xyuas cov iav compositon, filament hom, strand suav thiab xov paj constructon.

Hauv qab no yog qhov tshwj xeeb identficaton system rau ob tus qauv:

YARN NOMENCLATURE (ntxiv)

Piv txwv ntawm yarn identficaton system

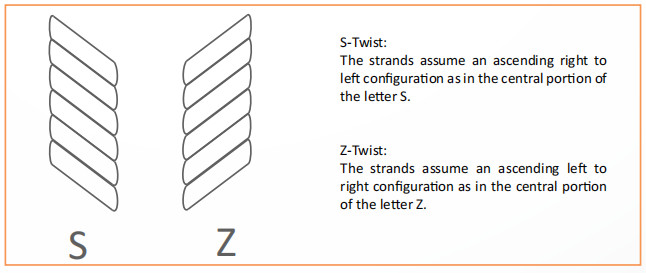

Twist ncaj qha

Lub twist yog siv mechanically rau yarns los muab cov txiaj ntsig ntawm kev txhim kho kev puas tsuaj, kev ua haujlwm zoo dua, thiab lub zog tensile ntau dua. Qhov taw qhia ntawm qhov twist yog ib txwm qhia nrog tus ntawv S lossis Z.

S lossis Z ncaj qha ntawm cov xov paj tuaj yeem lees paub los ntawm txoj kab nqes ntawm cov xov paj thaum nws tuav hauv vertcal positon

YARN NOMENCLATURE (ntxiv)

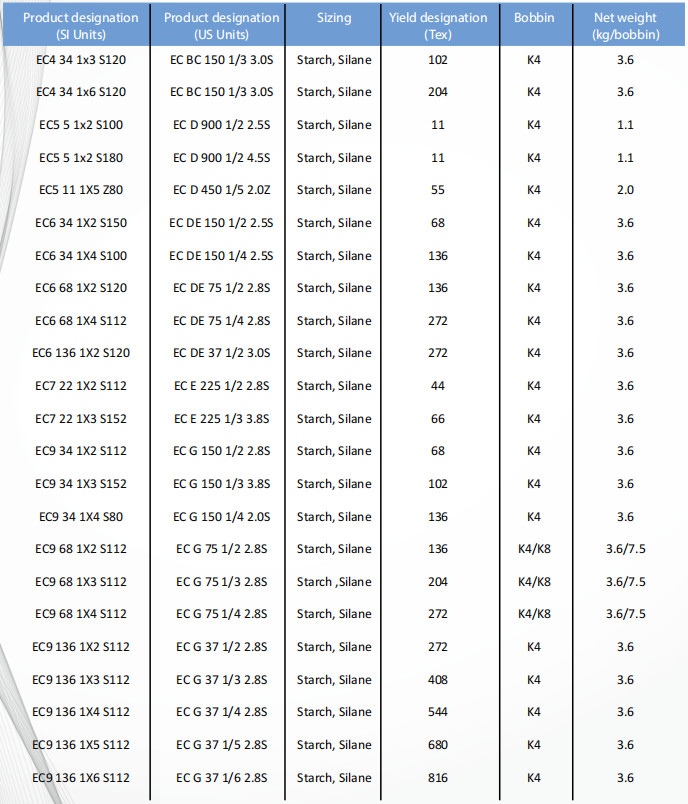

Cov xov paj diam - Sib piv qhov tseem ceeb ntawm US thiab SI system

| US Units (ntawv) | SI units (microns) | SI UnitsTEX (g/100m) | ApproxiateNum ntawm filaments |

| BC | 4 | 1.7 | 51 |

| BC | 4 | 2.2 | 66 |

| BC | 4 | 3.3 | 102 |

| D | 5 | 2.75 ib | 51 |

| C | 4.5 | 4.1 | 102 |

| D | 5 | 5.5 | 102 |

| D | 5 | 11 | 204 |

| E | 7 | 22 | 204 |

| BC | 4 | 33 | 1064 ib |

| DE | 6 | 33 | 408 |

| G | 9 | 33 | 204 |

| E | 7 | 45 | 408 |

| H | 11 | 45 | 204 |

| DE | 6 | 50 | 612 |

| DE | 6 | 66 | 816 ib |

| G | 9 | 66 | 408 |

| K | 13 | 66 | 204 |

| H | 11 | 90 | 408 |

| DE | 6 | 99 | 1224 |

| DE | 6 | 134 | 1632 ib |

| G | 9 | 134 | 816 ib |

| K | 13 | 134 | 408 |

| H | 11 | 198 | 816 ib |

| G | 9 | 257 | 1632 ib |

| K | 13 | 275 | 816 ib |

| H | 11 | 275 | 1224 |

Kev sib piv qhov tseem ceeb - Strand Twist

| TPI | TPM | TPI | TPM |

| 0.5 | 20 | 3.0 | 120 |

| 0.7 | 28 | 3.5 | 140 |

| 1.0 | 40 | 3.8 | 152 |

| 1.3 | 52 | 4.0 | 162 |

| 2.0 | 80 | 5.0 | 200 |

| 2.8 | 112 | 7.0 ib | 280 |

YARNS

E-iav Continuous twisted yarn

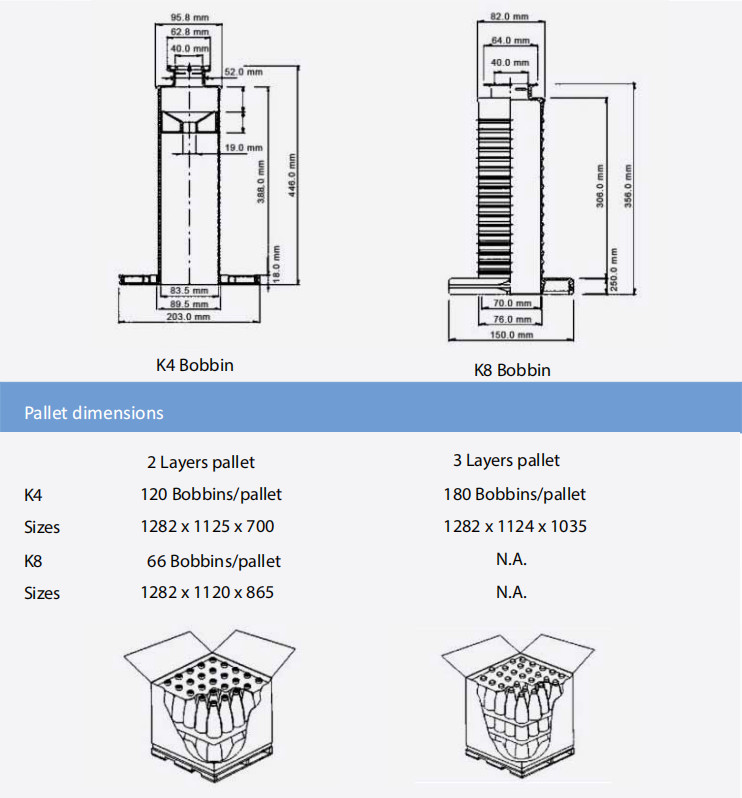

Ntim

E-iav Continuous twisted yarn